Plant and Process Technology

165

Plant and Process Technology

Modeling and simulation of chemical processes, equipment design, thermodynamic property data

Prof. Dr.-Ing.

Harald Klein

n

In 2016 the focus of research at the Institute of Plant and Process

Technology was the energy efficient design of chemical production

processes as well as innovative design methods for process equipment.

After intensive measuring campaigns in 2014-15 in the 1.2 m diameter

packed bed test column, the focus was shifted in 2016 to innovative

modeling of the maldistribution behavior in packed columns. Furthermore,

the research area of modeling and simulation of the dynamic behavior of

industrial chemical processes started within the consortium SynErgie in

the long-term BMBF project Kopernikus. Finally, in 2016 the first results

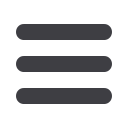

were generated based on complex CFD simulations which describe the

heat transfer phenomena during condensation of pure substances at the

outer surface of plain and low-finned tubes

in cooled heat exchangers.

www.apt.mw.tum.de harald.klein@tum.dePhone +49.89.289.16501

Contact

Modeling and Thermodynamic Property Data

A promising option to produce climate-

friendly biofuels is to grow algae in large

open ponds, extract the lipid content of

the algae cells and process it to a bio

refinery. The endproducts of this process

may be biodiesel or jet fuel. The algae

consume CO

2

to increase their biomass

and are then converted into bio-fuels.

A possible CO

2

source is the flue gas of

power plants which can either be used

directly as feed for the algae pond or from

which the CO

2

can be captured and then

CFD Simulation of condensation on a low-finned tube

used as a pure CO

2

feed gas. Although

growing algae in open ponds has been

done for decades, there is still a lot of

research necessary in how to efficiently

grow algae in large systems with a surface

area per pond of 10 ha and above, and

therefore produce biofuels economically.

Especially the design of larger algae

ponds remains a challenge since there

is virtually no practical experience in the

behavior of such large ponds.

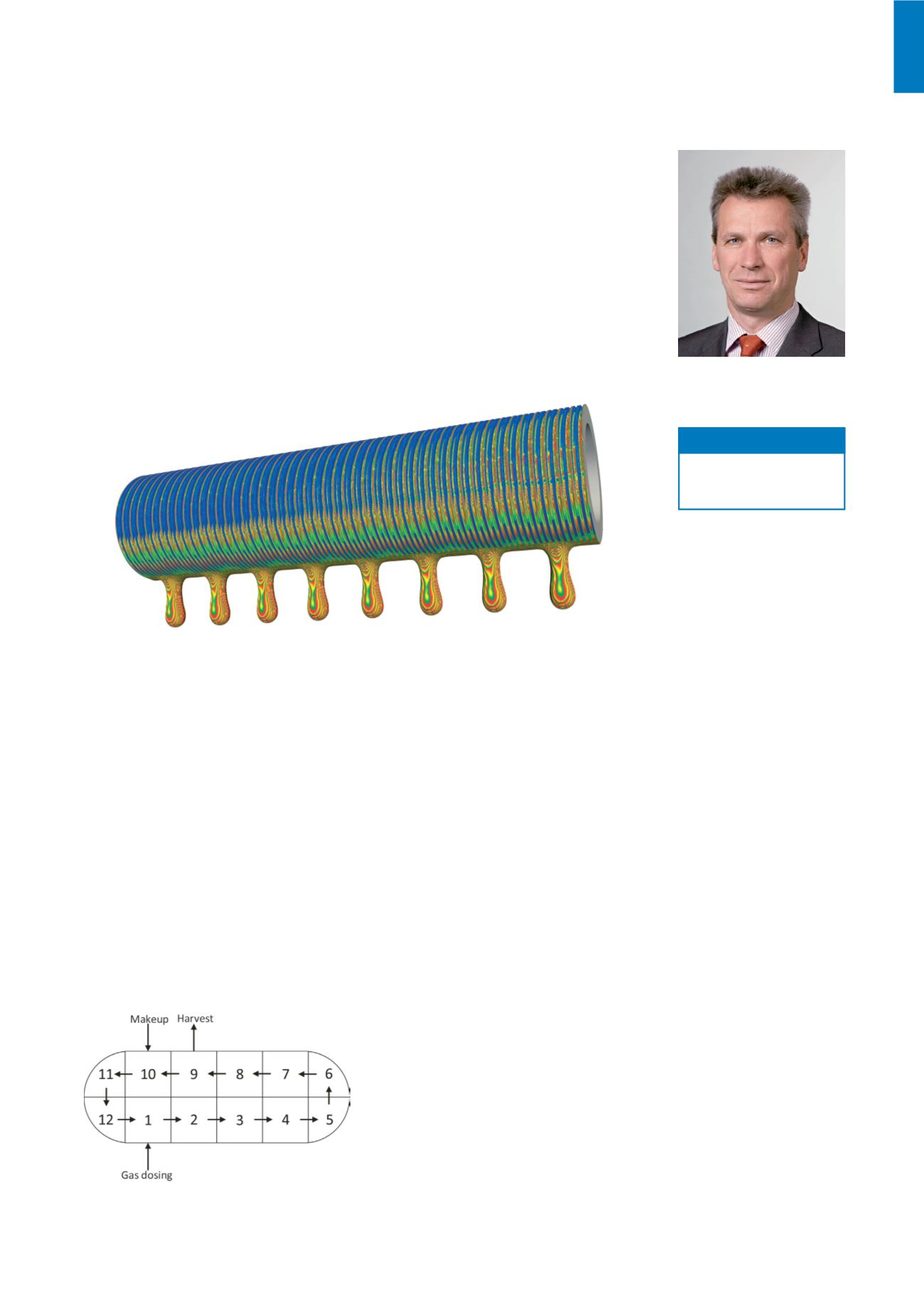

At the Institute of Plant and Process Tech-

nology a model was developed that simu-

lates the behavior of raceway-type large

open ponds. The model was programmed

in MATLAB and can be used to evaluate

the performance of open raceway-type

ponds at different locations and periods.

The model is fully dynamic and consid-

ers environmental effects like weather

changes as well as the dynamic behavior

of the pond caused by the coupling of

physical and biological processes.

Modelling of open algae ponds