196

Medical and Polymer Engineering

Medical and Polymer Engineering

Medical and polymer engineering, additive manufacturing, cell-based medical engineering

n

The Institute of Medical and Polymer Engineering deals with research

and teaching in the field of medical materials and their processing. The

development of medical plastics with biocompatible and bioactive prop-

erties is of particular importance. The Institute is a major contributor to the

teaching of the Master’s program in Medical Engineering.

The institute was founded in 2000 by Prof.

Dr. Dr. Erich Wintermantel. Since then the

focus has been set on the development

of biocompatible materials and process

technologies. After 16 years as the direc-

tor of the institute, Prof. Wintermantel left

the TUM on April 1st 2016. Since then the

institute has been headed by Prof. Lüth

and Dr. Eblenkamp.

In 2016 funding for several new research

projects were acquired: The

‘

AntiMic’

project develops innovative plastics with

antimicrobial effects. The ‘TheverTec’

project deals with the realization of

polymeric tooth coverings. A highlight

was the successful acquisition of EXIST

Forschungstransfer Funding by the Med-

Tech team AMmedical, which provides the

chair with four new positions in the field of

polymeric additive manufacturing.

Research Example: Additive Manufacturing

of Systems for Cell-based Medical Engineering

Additive manufacturing enables new pos-

sibilities to produce systems for cell-

based medical engineering. The main

advantages include functional integration

(sensors and actors), complex miniatur-

ized designs as well as high material and

cost savings. However, a fundamental

requirement is the development of

biocompatible materials for additive man-

ufacturing. In collaboration with an indus-

Prof. Dr. Tim C. Lüth

(interim)

www.medtech.mw.tum.de markus.eblenkamp@tum.dePhone +49.89.289.16753

Contact

trial partner a new printable biocompatible

material was developed and evaluated for

the production of innovative bioreactors.

The material was tested for biological

compatibility (cytotoxicity, genotoxicity/

mutagenicity, hemocompatibility) with

excellent results and was successfully

used to create a first printed bioreactor to

store corneal tissue until transplantation.

3D-printed bioreactor for tissue

cultivation (MedTech)

Cultivated cornea tissue in the

3D-printed bioreactor (MedTech)

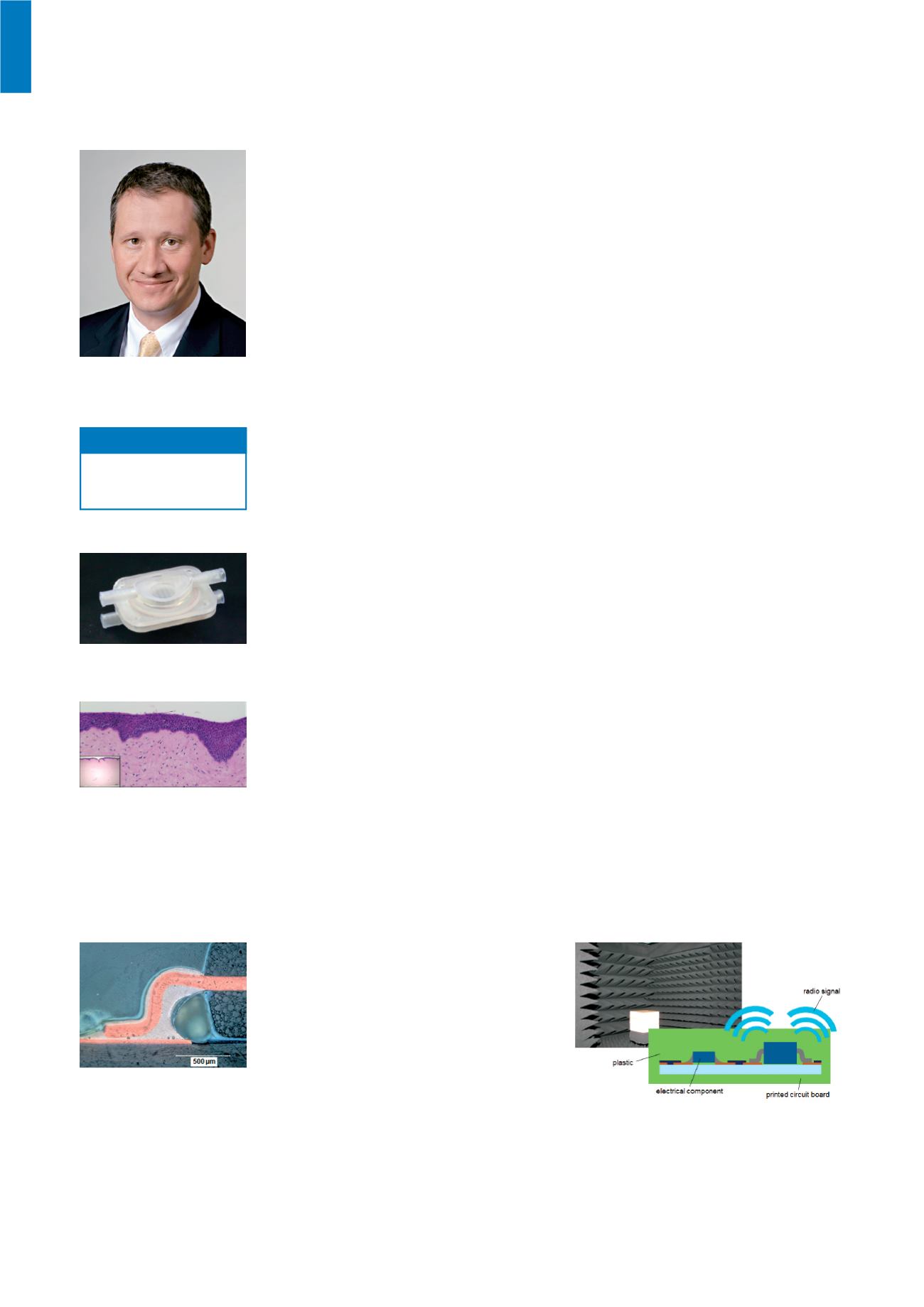

Research Example: SmartMold – Assembly-free Integration

of IoT Components into Medical Plastic Products

In 2016 the institute was involved in the

Zentrum Digitalisierung Bayern (ZD.B) and

co-founded the community of practice ‘IoT

and Materials’. In this context, the institute

explores the possibilities for the destruc-

tion-free integration of IoT components in

medical plastic parts without assembly. In

cooperation with the TUM Department of

Electrical and Computer Engineering the

influence of electromagnetic transmission

behavior by medically relevant plastics as

well as its modification by the design of

additively manufactured inner structures of

plastic parts is considered.

Analysis of the influence of electromagnetic transmis-

sion behavior by plastics within an anechoic chamber

Micrograph analysis of polymer

embedded electronic parts