Plasma Material Interaction

209

Plasma Material Interaction

Properties and optimisation of materials facing high temperature plasmas

Prof. Dr. Rudolf Neu

n

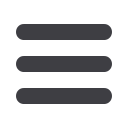

The highlight for the Plasma Material Interaction Group in 2016 was the

commissioning of a new scanning electron microscope which allows the

manipulation of samples with up to 10 kg weight and a size of up to 450 x

200 x 65 mm³.

The highlight for the Plasma Material

Interaction Group in 2016 was the

commissioning of a new scanning electron

microscope (SEM) equipped with a

focused ion beam (FIB) and combined

energy and wavelength dispersive x-ray

spectroscopy (EDX/WDX). Scanning

electron microscopy is one of the major

tools for the investigation of materials

which were exposed to plasma, because

it allows high lateral resolution where other

diagnostics deliver only area averaged

properties. The outstanding feature of the

new device is the specimen stage which

allows the manipulation of samples with

up to 10 kg weight and a size of up to

450 x 200 x 65 mm³. This will enable us

to perform investigation on complete com-

ponents without cutting them into small

samples, opening up the comparison of

the pre- and post-exposure status and

allowing truly non-destructive analysis.

The WDX feature provides us with com

position maps with highest resolution for

the elements involved.

www.pmw.mw.tum.de Rudolf.Neu@ipp.mpg.dePhone +49.89.3299.1899

Contact

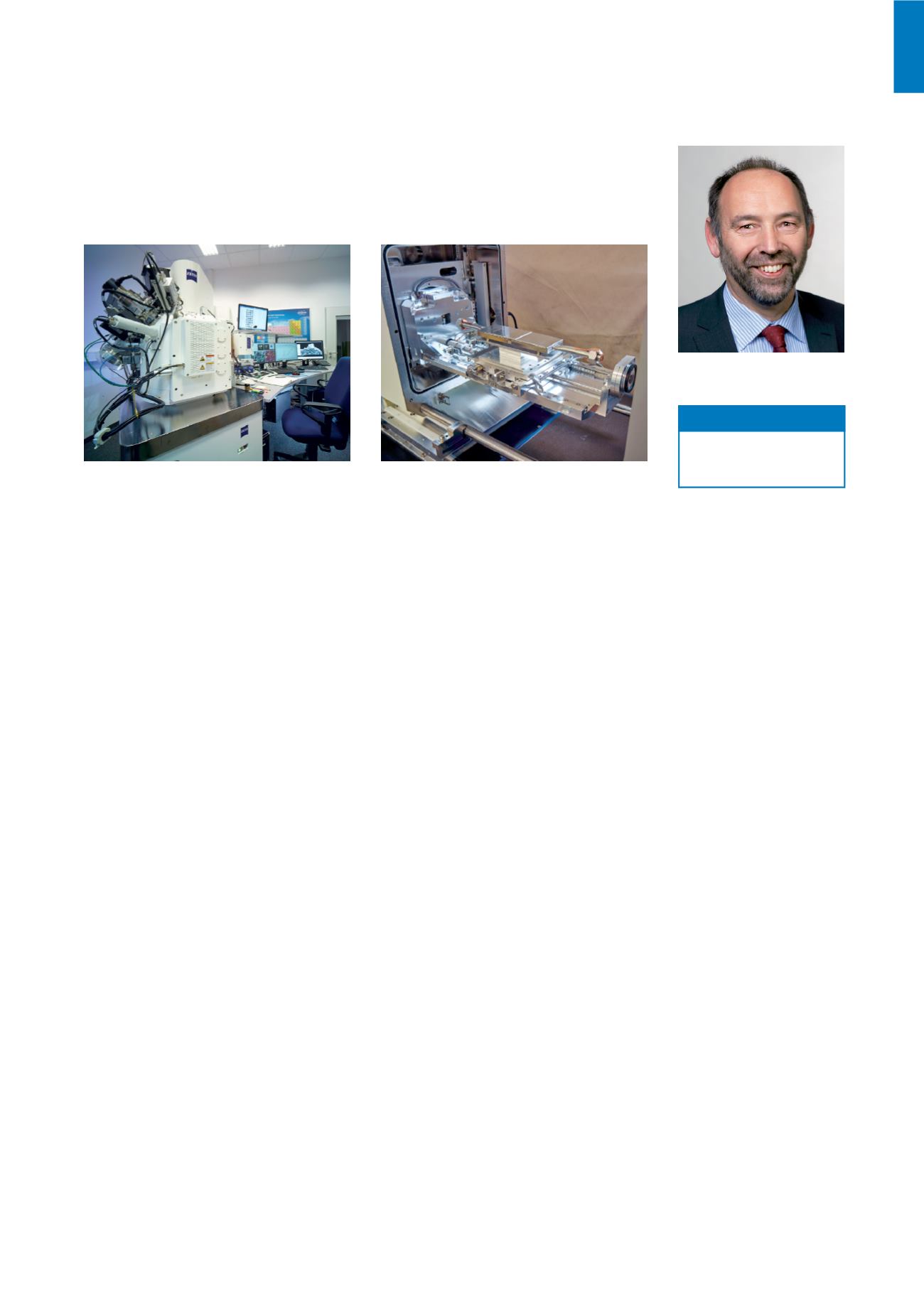

Fig. X1: New scanning electron microscope (left) equipped with a stage (right, with mounted plasma facing compo-

nent) capable of handling large specimens

Self-Passivating Tungsten-Alloys as

First Wall Material in Fusion Devices

An interesting application of the SEM is

the investigation of so-called self-pas-

sivating tungsten alloys after oxidation.

Such W alloys typically consist of tungsten

(W), chromium (Cr) and small amounts of

titanium (Ti) or yttrium (Y). They are the

subject of present day research because

these alloys could strongly suppress the

formation of WO

3

at temperatures above

800 °C. This might be important in a

potential loss of cooling incident together

with additional air or water ingress in

the vacuum chamber of a future fusion

reactor: self-passivating W alloys would

strongly reduce the emission of activated

W in the form of volatile tungsten oxide.

For solar thermal power plants these W

alloys might be used as material for the

thermally highly loaded receiver avoiding

strong corrosion.

Fig. X2 shows a sample of W-10Cr-2Ti

alloy (numbers given in wt. %) before

and after exposure to 20% O

2

/80% Ar at

1000 °C for 4 hours. On the flat surfaces

only small oxidized areas can be found

whereas at the edges oxidation is clearly

visible. Obviously, the passivating Cr

2

O

3

layer, although reducing the parabolic oxi-

dation rate at 800 °C by a factor of about

300, is not stable at 1000 °C and oxidation

of W progresses from the weakest points.