Machine Elements

257

Machine Elements

Calculation, simulation and experimental analysis of gears, synchronizers, clutches and rolling element bearings

n

The Institute of Machine Elements (FZG) focuses on the development

of methods and tools for reliable determination of fatigue life, efficiency,

friction and vibration characteristics of gears and transmission elements.

Prof. Dr.-Ing.

Karsten Stahl

Cylindrical Gears

The Institute of Machine Elements, also

known as ‘Gear Research Centre’ (FZG),

is an established internationally-renowned

research centre for gears and transmis-

sions. The development of methods and

tools for reliable determination of fatigue

life, efficiency and vibration characteristics

of gears and transmission elements is

the primary focus of research activities at

FZG. FZG has state-of-the-art facilities for

the examination and testing of different

machine elements – such as gears, syn-

chronizers, clutches and rolling element

bearings.

The research projects of FZG range

from theory-oriented basic research to

application-related work. The projects

are financed and supported by different

organisations. A large number of these

projects are initiated, financed and

supervised by the Forschungsvereinigung

Antriebstechnik e.V. (FVA), usually together

with the Arbeitsgemeinschaft industrieller

Forschungsvereinigungen (AiF). Other

important research partners include the

Deutsche Forschungsgemeinschaft (DFG),

the Bayerische Forschungsstiftung, the

Deutsche Wissenschaftliche Gesellschaft

für Erdöl, Erdgas und Kohle e.V. (DGMK),

the FVV or the Stahlforschung. In addition,

many application-oriented projects are

requested and commissioned directly by

industry.

Our lecture series and practical exercises

in machine elements represent the basic

training in mechanical engineering. In the

lectures, students learn to select machines

and machine elements correctly, to design

them and to calculate their properties. This

knowledge is then practically applied in

practice in design and calculation exam-

ples within the lecture-related exercises.

A very important aspect of this is that

the students learn to communicate using

‘engineers’ language’ – with sketches and

drawings. Practical relevance and topicality

are also an important criteria for lectures

in special subjects. Last but not least,

this relevance is ensured with lectures by

executives from industry.

www.fzg.mw.tum.de fzg@fzg.mw.tum.dePhone +49.89.289.15807

Contact

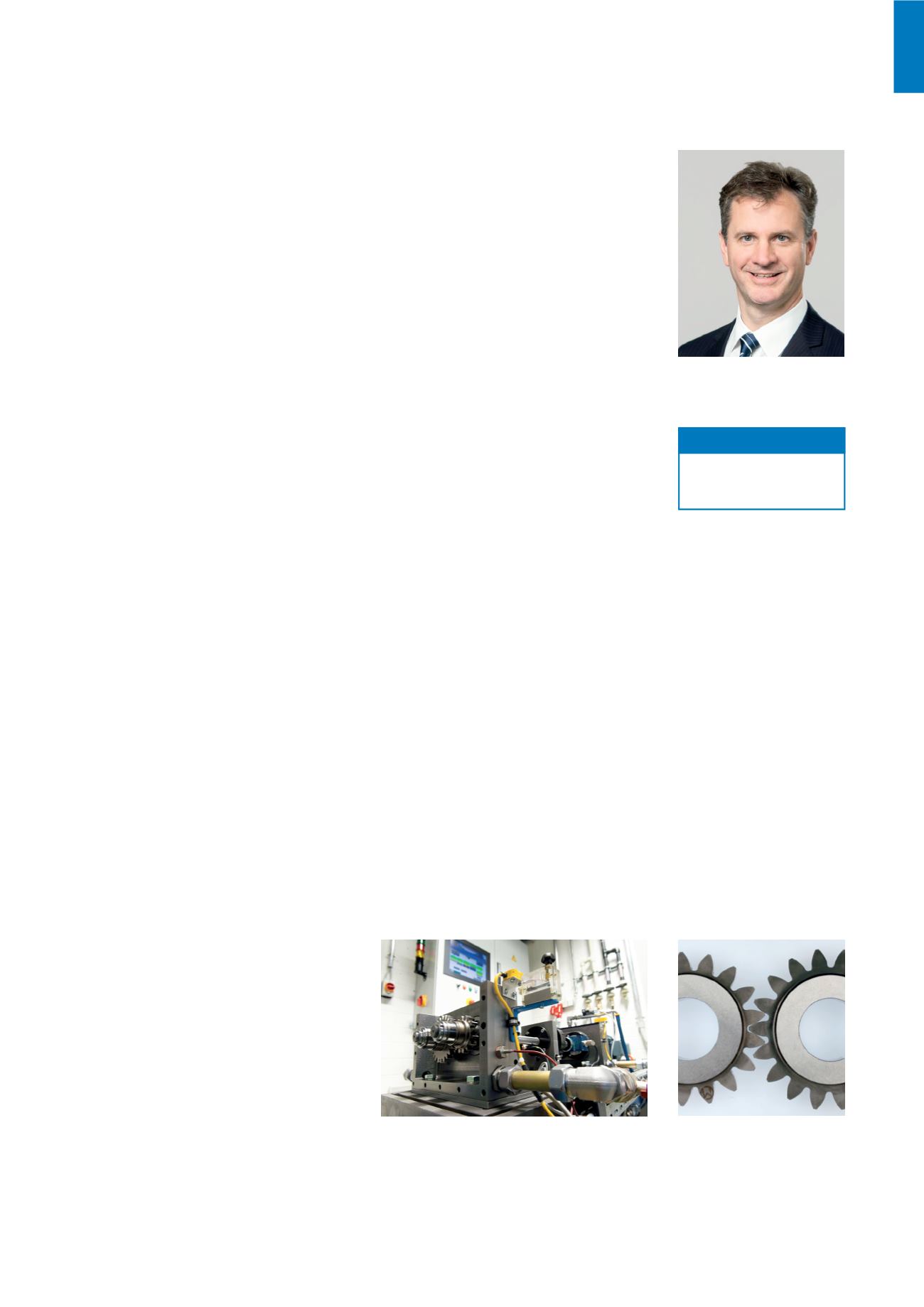

Back-to-back gear test rig

(a=91.5mm)

Research Components

The focus of research activities is the experimental and theoretical examination of

gear components and drive systems.

Cylindrical gears are the most common

types of transmission. The fatigue life

of cylindrical gears is limited by pitting,

micro-pitting, scuffing, wear, tooth root

breakage or tooth flank breakage. The

basis for the experimental examination of

such gear damage is the standard FZG

back-to-back gear test rig, which was

developed by FZG and is used all over the

world.

The types of damage described, as well as

material, lubricant and efficiency examina-

tions for external and internal gearings, can

thereby be carried out very efficiently. In

addition to sufficient load-carrying capacity

and good noise characteristics, research

is increasingly focusing on the efficient

performance of gears.