290

Internal Combustion Engines

Internal Combustion Engines

Engine design and simulation, combustion technologies, and experimental evaluation

Prof. Dr.-Ing.

Georg Wachtmeister

Combustion Technologies – CFD-Simulation –

Emission Reduction

The reduction of engine emissions and

fuel consumption are drivers for the

improvement of combustion technology.

Engines for gasoline, diesel, and natural

gas are developed and built at the institute

and are available for industrial or public

funded research projects. A key com-

petence for the realization of our engine

concepts is the application of professional

CFD simulation software, which is used

to predict and optimize the gas exchange

n

The focus of the Chair of Internal Combustion Engines in 2016 was to

extend efforts on the reduction of engine-out emissions by enhancing

combustion technology, engine after-treatment, emission measurement

techniques, and the knowledge on fuel properties and fuel composition.

Favorable emission behavior, high efficiency and low complexity of

internal combustion engines will be crucial in the future, as alternative

drive technologies emerge. Especially for long-distance or high-power

applications, internal combustion engines will have to ensure clean and

sustainable mobility and energy supply today and tomorrow.

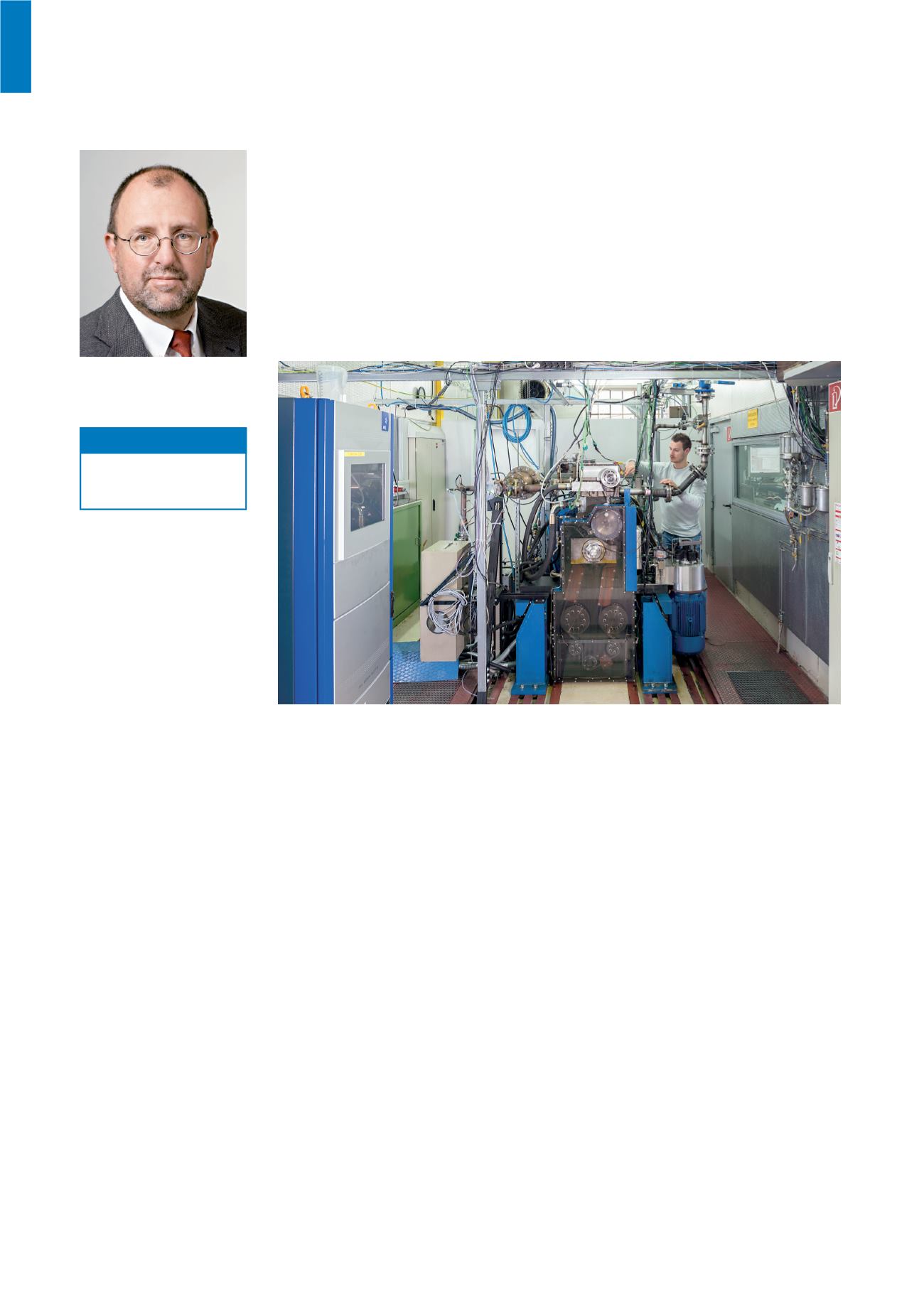

A highlight in 2016 were the first experi-

mental results using oxymethylene ether

(OME) fuel in a diesel engine. OME burned

almost without releasing particles and

showed extremely low concentrations of

harmful substances in the raw exhaust

gas. Using a simple oxidation catalyst,

the tailpipe emissions were below the

www.lvk.mw.tum.de lvk@lvk.mw.tum.dePhone +49.89.289.24101

Contact

phase, in-cylinder swirl, tumble or turbu-

lence, and the phases of fuel injection,

mixture formation, and combustion. Simu-

lation results are used to design improved

geometries of the combustion chamber or

injector nozzles and are then validated on

one of our 13 engine test benches. Engine

out emissions are measured by means of

up-to-date FTIR technology and a modern

particle counting system. We use compo-

nent test benches to evaluate hydraulic

strict Euro VI limits even without using

a particulate filter or SCR system. OME

is a synthetic fuel and can serve as a

storage medium for fluctuating renewable

energy in a CO

2

-neutral future. The costs

of OME production are estimated below

20% compared with conventional E-fuels

(Fischer-Tropsch).

Test bench with clean OME single

cylinder engine