324

Machine Tools and Manufacturing Technology

Machine Tools and Manufacturing Technology

Perspectives for production

Prof. Dr.-Ing.

Michael F. Zaeh

Machine Tools

In the context of the Machine Tools

working group, we analyze and optimize

cutting production systems. The studies

focus on the examination of dynamic

machine behavior, the cutting process

and influencial thermal factors. Thanks

to the consideration of aspects of instru-

mentation and control, the study horizon

is expanded beyond purely mechanical

structures to complex mechatronic sys-

tems. Modern simulation methods, such

as the finite elements and multiple-body

simulation, are used for these exami-

nations in order to reflect the machine

features in detail. By coupling these with

developed cutting-force models, inter-

actions between structure and process

can be demonstrated. Furthermore,

energy-related aspects which interact with

the machine properties are in the focus of

the investigations. The energy efficiency of

machine tools is becoming more and more

a competitive factor.

n

In 2016, the focus of the Chair for Machine Tools and Production

Engineering was on the machining of materials and the processing thereof

into composite materials. With emphasis being placed on lightweight

design, new production processes were analyzed and further optimized

using suitable simulation models.

With regard to light-weight structures that

are optimally adapted to the respective

loads, bionic approaches such as the

adaptation of natural honeycomb and grid

structures have proven to be particularly

suitable for achieving the desired goals in

the area of additive production processes.

With the objective to use the suitable

material in any location, the research

acivities are focusing on the area of joining

and separating cutting technologies are

focusing on producing joints of different

dissimilar metals or metal to plastics that

so far could not be produced. Thermal

simulation models of joining processes

have proven their particular potential,

which allow the development of innovative

production processes e.g. in the produc-

tion of lithium-ion cells.

For the last past 21 years, the Application

Center Augsburg has transferred the new

production technologies to industrial

production, from which mainly small and

medium-sized companies in the Bavarian-

Swabian region benefit.

www.iwb.mw.tum.de info@iwb.tum.dePhone +49.89.289.15500

Contact

Test of milling in the context of the new learning

factory for optimal cutting

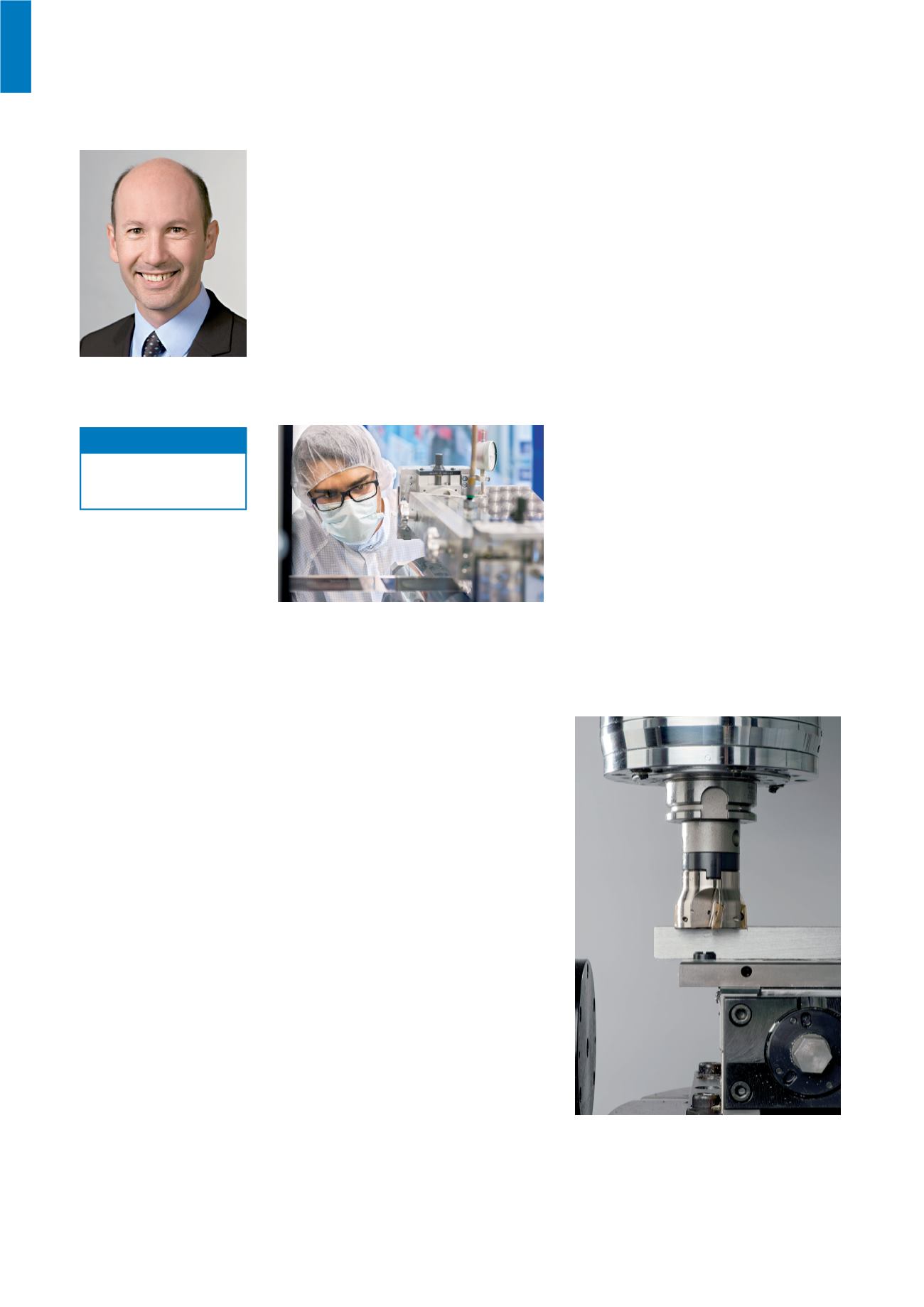

Monitoring the process for coating anodes