Micro Technology and Medical Device Technology

189

Micro Technology and Medical Device Technology

Computational design and rapid manufacturing of certified devices, mechanisms and robots

n

The focus of the Institute of Micro Technology and Medical Device

Technology is to accelerate the process of developing ideas into pro-

ducts. In research and science, the time required for implementation is

a significant factor for success. Therefore, rapid prototyping and rapid

manufacturing technologies are part of our main research interest. We

are systematically developing and analyzing new rapid technologies, as

well as applying them in the areas of precision engineering, micro tech-

nology and medical device technology. We are systematically validating

our research devices to achieve reliable scientific results. In the area

of medical technology, we develop according to ISO 13485, certify our

devices according to MDD/FDA and perform clinical studies according to

ISO 14155.

Task-Oriented, Computational Kinematic Design

Prof. Dr. Tim C. Lüth

www.mimed.mw.tum.de sekretariat@mimed.dePhone +49.89.289.15190

Contact

This year an extensive project on fun-

damentals to support nursing through

technical systems and infrastructures

was finalized. It was funded by the Alfried

Krupp von Bohlen und Halbach-Stiftung

and started in 2014. Our cooperation with

the nursing home KWA Luise-Kiessel-

bach-Haus turned out to be an important

success factor. Within the project we

focused on systems to assist both

caregivers and patients. We evaluated

passive force assisting devices for care

givers. In order to prevent dehydration,

we developed a system to automatically

detect the liquid intake of patients using

a detection cup, a detection straw and

a base station. We also developed a

lift-assist device to assist patients in

rising from a chair. The prototypes will be

further evaluated at the nursing home in

order to be able to realize ready-to-market

products.

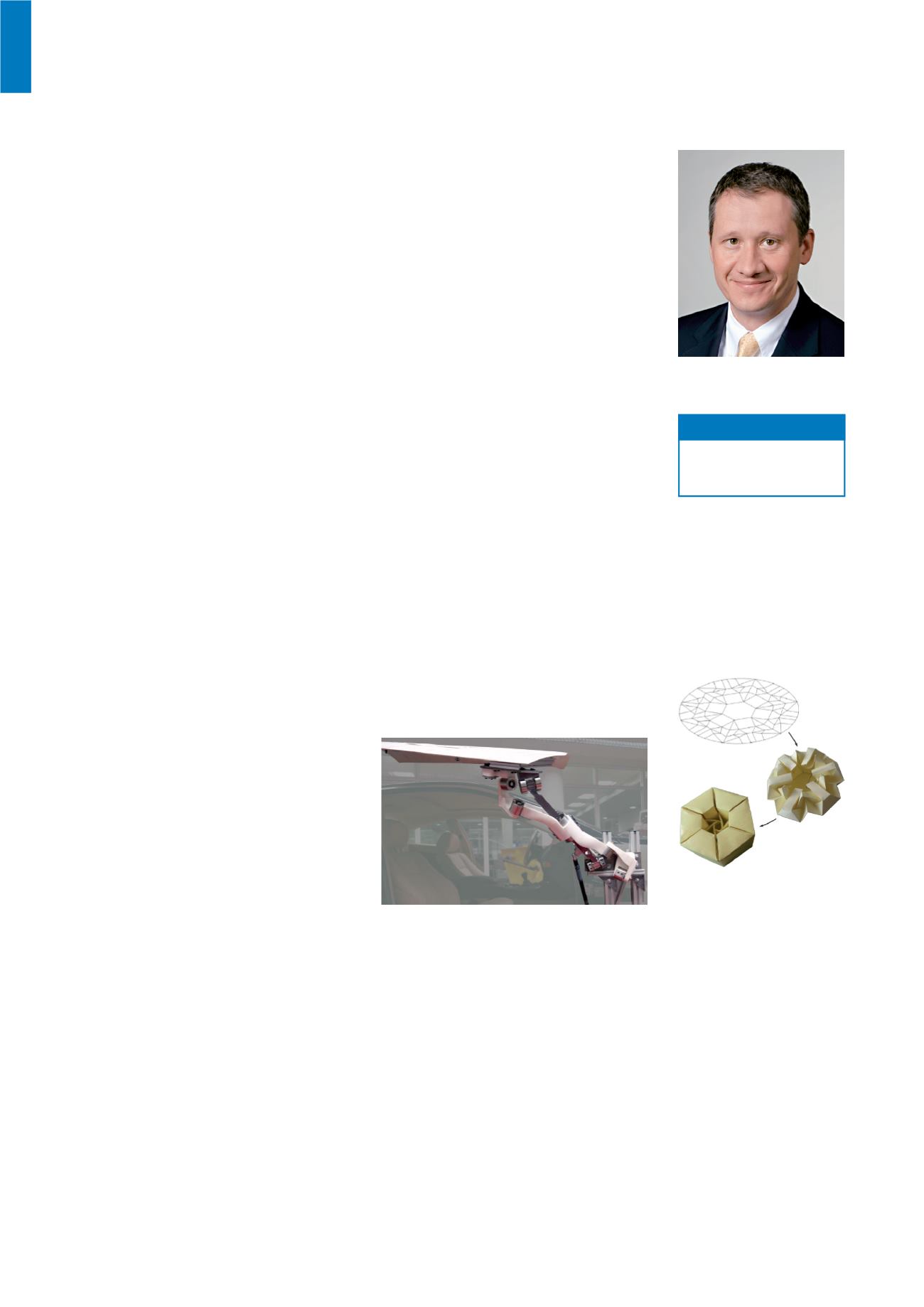

pattern design. In another project (foun-

ded by the Bavarian Research Foundation

and in collaboration with BMW AG and

Webasto Edscha Cabrio GmbH), another

optimization based kinematic synthesis

approach was developed, which consi-

ders multiple pose synthesis with respect

to given space requirements in CAD-integ-

rated design processes.

Based on preceding analysis, synthesis

and design results the proof of concept

The initial and fundamental idea of

mechanism and machine theory consist

in designing mechanical devices with

task-specific mobility and dimensions

and represents also one of the basic

design methodologies behind linkage and

robotic motion systems developed at the

institute. In this context, the major goal of

the kinematic design group is to provide

computer-aided analysis and synthesis

methods that allow for the design and

prototyping of novel task-specific motion

systems.

This year a result in the area of computati-

onal synthesis methods was the develop-

ment of a novel formalism for membrane

folding pattern design based on concepts

of finite rigid motion and spherical

kinematic synthesis. These techniques

combine successively to segment a flat

bounded surface, such that it can reach

a prescribed spatial configuration. The

specific result is a creative but systematic

and computational procedure for crease

Example of the formalism for

membrane folding pattern design;

a hexagonal prism folding for

membrane packaging based on

concepts of finite rigid motion

and spherical kinematic synthesis

(MiMed)

Prototype of a compact, origami-inspired spatial car

door guidance linkage, which eases getting into a car

in cramped parking spots (MiMed)