71

Production and Logistics

n

Production technology is – in addition to the automotive industry – Germany’s top export

and one of the pillars of the Department of Mechanical Engineering since its inception.

Increasing Electric Drive Efficiency by an Optimized Production Process

For a long time, special emphasis has been placed on

integrating enhancements into the entire process chain,

from the design phase to the customer, rather than

considering individual stages in isolation. Closely related

to this are fundamental research and application, such as

the question of how to simulate and suppress oscillations

in production machinery, how to implement models for

optimization of the design and production process, or how

new materials can be processed resource-efficiently. A

sample of production technology highlights follows:

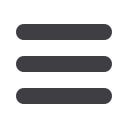

In order to convert electric into kinetic energy in an electric

drive, magnetic fields must be generated. Therefore the

magnetic properties of the electric drives’ main compo-

nent, the so-called electrical sheet metal, are decisive for

its efficiency. It has been shown, that the manufacturing

process of the electrical sheet metal has a negative

influence on its magnetic properties. This is mainly due

to the residual stresses induced in each processing step.

Especially when looking at the blanking process, the

manufacturing parameters have a significant impact on

the magnetic properties. Using optimized blanking param-

eters can decrease the losses and the electricity demand

of an electric drive.

This work is funded by the Deutsche Forschungsgemein-

schaft (DFG, German Research Foundation) – 218259799

and carried out in the research unit project – ‘FOR 1897

– Low-Loss Electrical Steel for Energy-Efficient Electrical

Drives’.

Microscopic image of an electric drive’s blanked stator

SynErgie – Synchronized and Energy-adaptive Production Technology for Adapting Industrial

Processes to a Fluctuating Energy Supply – Project Cluster Production Infrastructure

The SynErgie project, with its more than 50 partners,

aims to create within the next ten years all technical and

market requirements in line with legal and social aspects

in order to effectively synchronize the energy demand of

German industry with the volatile energy supply. SynEr-

gie thus contributes to the cost-efficient realization of

renewable energies and enables Germany to develop into

an international leader for flexible industrial processes and

technologies.

The project ‘SynErgie’ is funded by the Federal Ministry of

Education and Research (BMBF). We would like to thank

the BMBF for its excellent support. For more information,

see

www.kopernikus-projekte.deUse of smart devices in adapting industrial processes to a fluctuating

energy supply