218

Industrial Management and Assembly Technology

Perspectives for production

n

The Chair for Industrial Management and Assembly Technology is one of the largest research

centers in Germany. In 2017 we considered in particular the possibilities of how humans can be

integrated into the objectives of Industry 4.0. In addition, the further development of electromobility

in Germany’s production area was specifically targeted.

Founded in 1875 the Institute for Machine Tools and

Industrial Management (

iwb

) at the Technical University

of Munich is one of the largest research institutions for

production technology in Germany. It encompasses

two chairs at the Faculty of Mechanical Engineering in

Garching near Munich.

In addition to all technological developments in the

context of industry 4.0 humans also play a central role

in the factory of the future. In order to be able to make

reliable statements about the potential and dangers of

its networking with the production system, the research

field ‘Man in the factory’ set up and commissioned an

experimental and learning laboratory. With the Mittelstand

4.0 Competence Center Augsburg, a contact point for

digitization and industry 4.0 topics is available for small

and medium-sized companies in the region of Bavaria.

In line with the structural conditions on site, the center’s

range of services is geared to manufacturing industry,

which is strongly represented there.

The focus is on industry and craft enterprises in mechani-

cal engineering, the manufacturing of metal products and

electronic products as well as vehicle construction. The

center’s offer is of course also available to companies

from other sectors. An important field of research is the

planning and control of autonomous production that is

based on cyber-physical systems, where the customer-in-

novated products will be produced. It is linked directly to

the open-innovation platform to ensure that the customer

is always well informed of the feasibility of their design,

and at the same time receives a delivery schedule and

cost estimate.

In the next few years the

iwb

will be involved in the

EU Horizon 2020 research project ‘PreCoM’, which

investigates the concept of predictive maintenance in

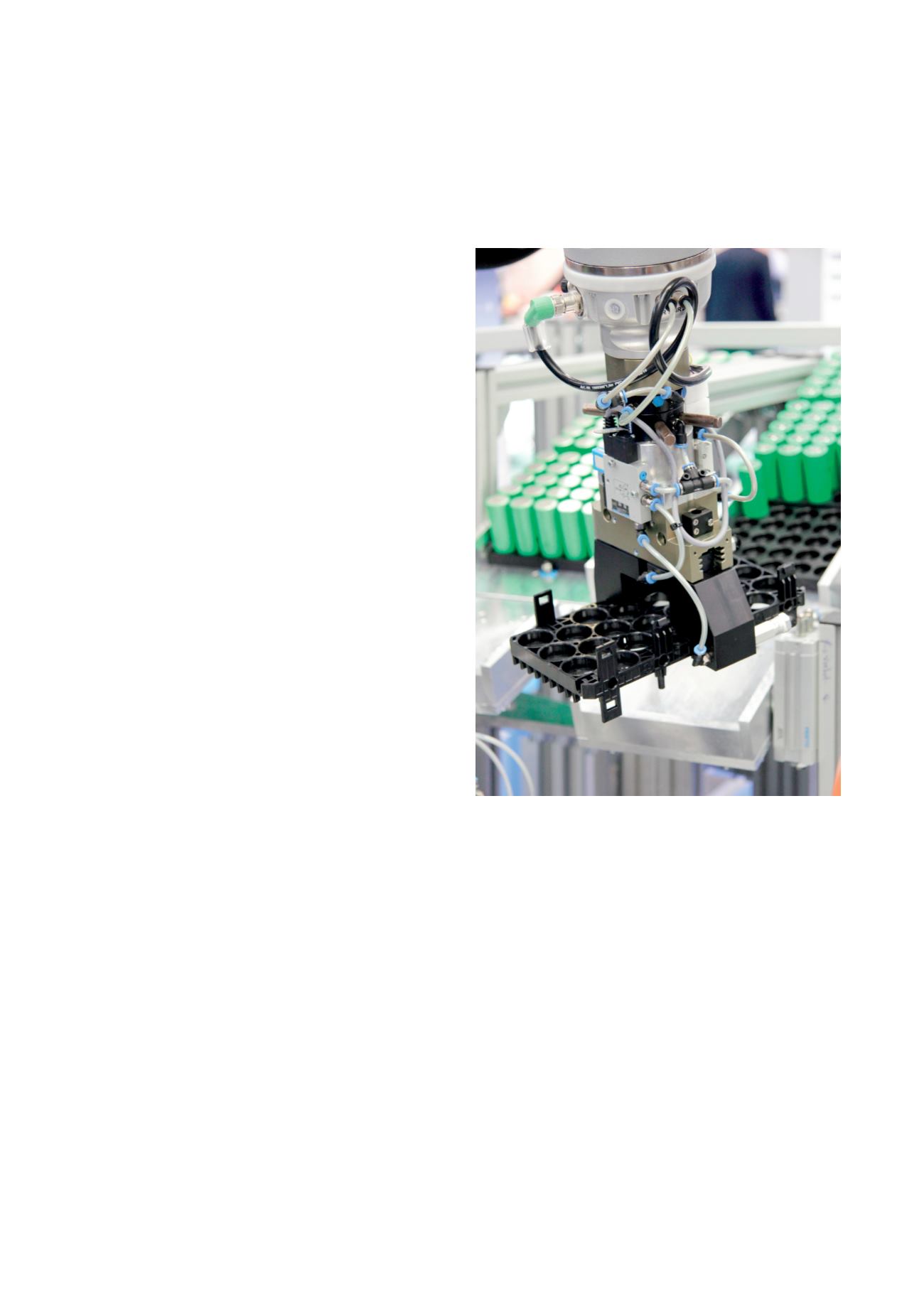

Combined jaw suction pad for handling of cell holders

conjunction with production planning, in order to increase

machine availability. The results offer companies a very

innovative business model with the opportunity to position

themselves on the market with customer-innovated prod-

ucts, and to strengthen Germany’s position as a business

location in the long term.