169

Plant and Process Technology

Modeling and simulation of chemical processes, equipment design, thermodynamic property data

The Institute of Plant and Process Design is a research center in the area of plant and process

engineering with a strong focus on thermal separation processes like distillation, rectification,

absorption and desorption, heat exchange and membrane processes. The research is organized

in the three focus areas of process design, equipment design methods, modelling as well as

thermodynamic property data. Thereby, modern experimental methods along with state of the art

mathematical software tools like dynamic simulation and computational fluid dynamics are widely

used in the research activities.

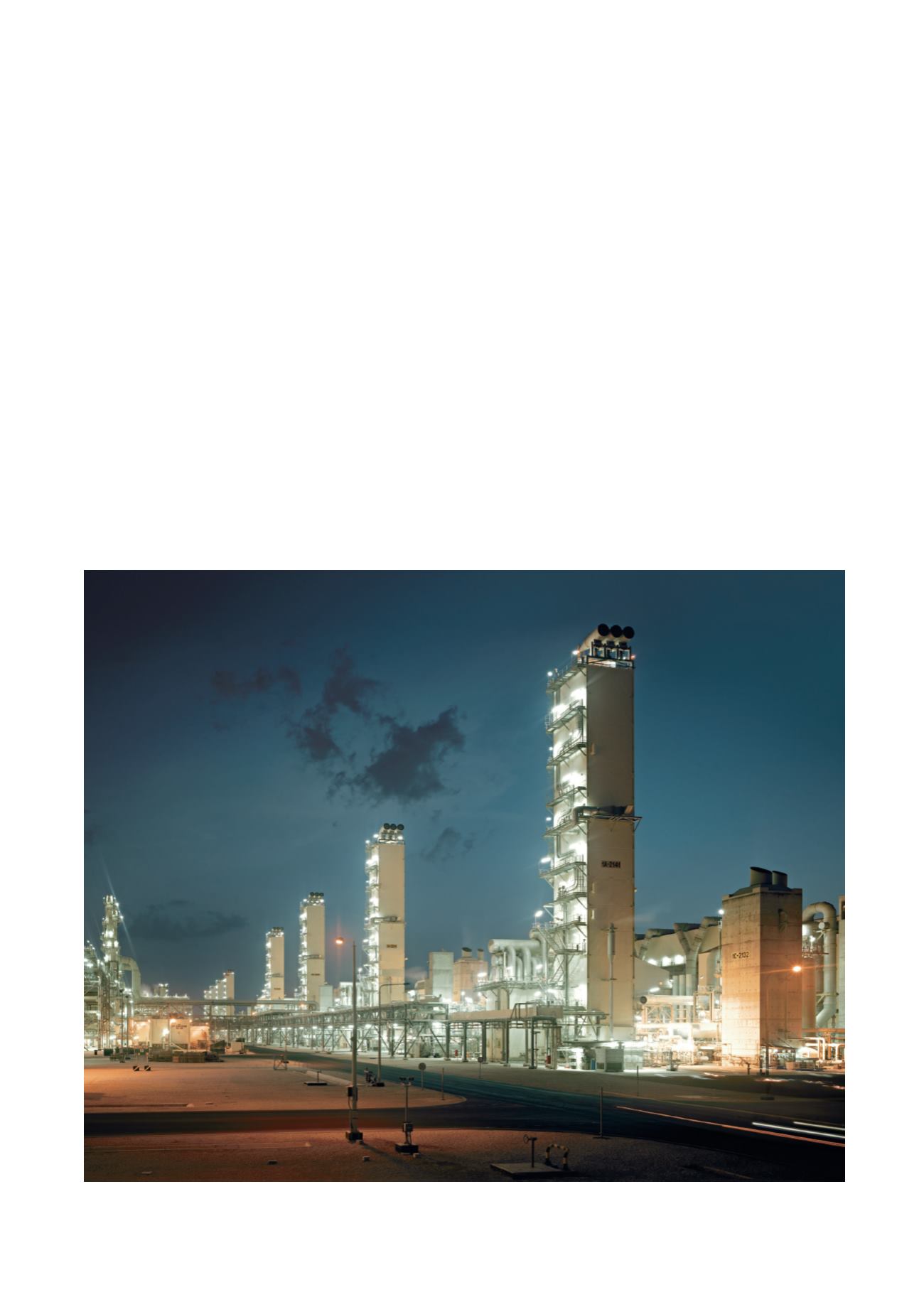

Process Design

Energy intensive chemical production processes like

alumina production and air separation can contribute to

stabilize fluctuating electric energy grids and markets.

However, chemical production processes are presently

not designed for dynamic operation modes with rapid

load and process changes. Therefore, it is necessary to

demonstrate which process and equipment modifications

are required in order to operate processes like air separa-

tion under severe dynamic conditions. Within the SynErgie

Picture of a typical air separation plant (provided by Linde AG)

consortium of the long term BMBF project Kopernikus

the energy intensive process for air separation units (ASU)

was selected as a fast track example. As a target air

separation plants will be enabled to contribute to stabilize

fluctuating electric energy grids and markets which will be

required when renewable energy sources such as wind

and solar power will lead in the long term to fluctuating

energy supply.