137

Non-destructive Testing

Quality control, non-destructive testing and structural health monitoring

■

The focus of the Chair of Nondestructive Testing in the field of mechanical engineering in 2017

was to establish NDT methods for the inspection of fiber reinforced materials (CFRP and GFRP)

together with partners in the automotive and aeronautic industries.

Further research is conducted in the field of wind energy:

structural-health-monitoring of tower and basement and

non-destructive testing of rotor blades. In civil engineer-

ing, the focus was on inspection techniques for construc-

tions of the infrastructure, the development of self-healing

techniques for concrete and for the detection of vertical

cracks in concrete pavements of highways (solving the

blow-up problem). In addition, several projects in the field

of cultural heritage have been conducted in close cooper-

ation with the Deutsches Museum.

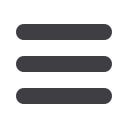

Computed Tomography of Otto Lilienthal’s Gliding Apparatus

More than 125 years ago, Otto Lilienthal laid the foun-

dation for modern aviation with his innovative gliding

apparatus, the ‘Normal Segelapparat’. Only four speci-

mens of the gliding apparatus have survived to this day,

one of them at home in the Deutsches Museum in Munich.

Computed tomography investigations carried out by the

Otto Lilienthal’s gliding apparatus

(Deutsches Museum)

Chair of Non-destructive Testing in collaboration with

Airbus have for the first time provided a glimpse into the

inner workings of the construction design. The images

will help researchers and conservators from the Chair of

Restoration, Art Technology and Conservation Science as

well as the Deutsches Museum during restoration.

Self-healing Materials

The aim of this project is the development of structures

made of self-healing concrete having an inherent healing

mechanism that becomes active when a crack appears,

thus rendering manual crack repair completely obsolete.

In order to obtain such automatic crack closure, European

project partners are investigating the use of PU-based

polymer precursors, superabsorbent polymers and bac-

teria. The role of the Institute of Non-destructive Testing

is to support the design of such healing agents as well

as the development of testing methods as tools for the

stakeholders to prove self-healing efficiency. Experimental

results of small-scale tests confirm the capability of

selected NDT methods to characterize material properties

plus the healing process and its efficiency.

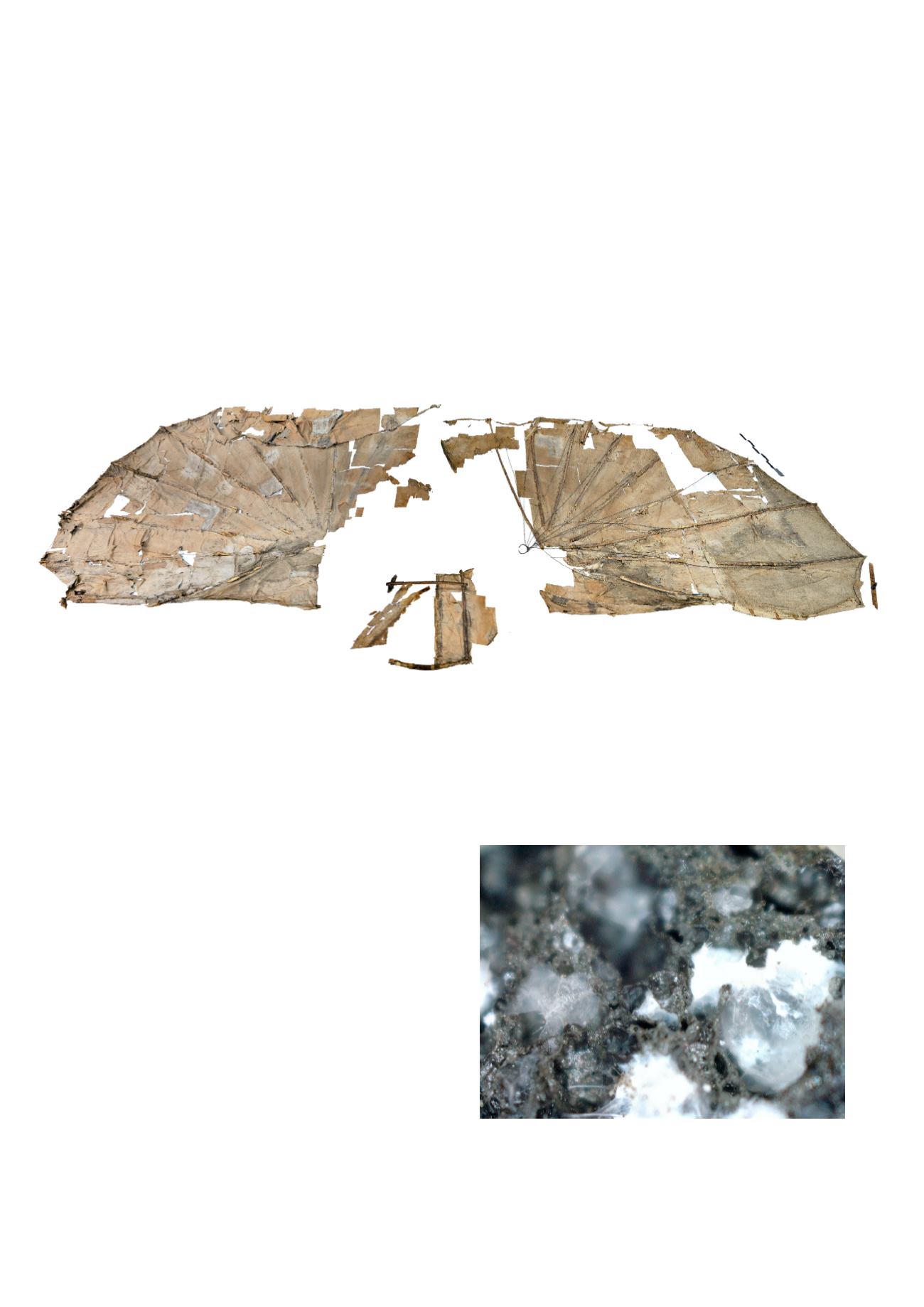

Microscopic image of bacteria-based self-healing agent stored in LWA

(lightweight aggregate).