274

Materials Science and Mechanics of Materials

Experimental and theoretical characterization of metallic materials

n

For many decades technological advances have been closely linked to the availability of

appropriate materials. The Institute of Materials Science and Mechanics of Materials (WKM)

concentrates on processing – microstructure – (mechanical) properties – relationships of load

bearing metallic materials such as high strength steels, titanium, nickel, aluminum and tungsten

alloys. Research is performed employing theoretical, numerical and experimental techniques with

equal importance on multiple length scales. The associated State Material Testing Laboratory

serves as an important interface to industry with respect to research oriented (offroutine) testing

of materials.

In 2017 research activities were directed toward plasticity

and failure of gas turbine sealing systems, hot isostatic

pressing of aluminum alloys in combination with precip

itation hardening, the hot isostatic pressing of iron-nickel-

titanium-aluminum-chromium high entropy alloys, plas-

ticity of high strength sheet steels for automotive applica-

tions and measurement of residual stresses. Much effort

is devoted to fundamental research in thermodynamically

based modelling of additive manufacturing and crystal

plasticity modelling and its application in microelectronics.

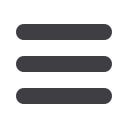

Schematic drawing of distorted crystal lattice due to a random arrangement

of alloying elements in a high entropy alloy (HEA). (Source: WKM)

Combined Hot Isostatic Pressing and Heat Treatment of Aluminum Cast Alloys

Aluminum cast alloys have multiple applications in the

automotive and aeronautical industries. In the field

of aircraft applications, high demands on the fatigue

resistance lead to the necessity for a special production

route that ensures high component quality. Hot isostatic

pressing (HIP) is commonly used to reduce casting

porosity of cast materials thereby significantly increasing

the material’s fatigue resistance. For the aluminum cast

alloy A356 (Al + 7% Si + 0.3% Mg) this is usually done

in a separate process step preceding the regular heat

treatment, which comprises solution annealing and aging.

Solution annealing followed by rapid cooling results in

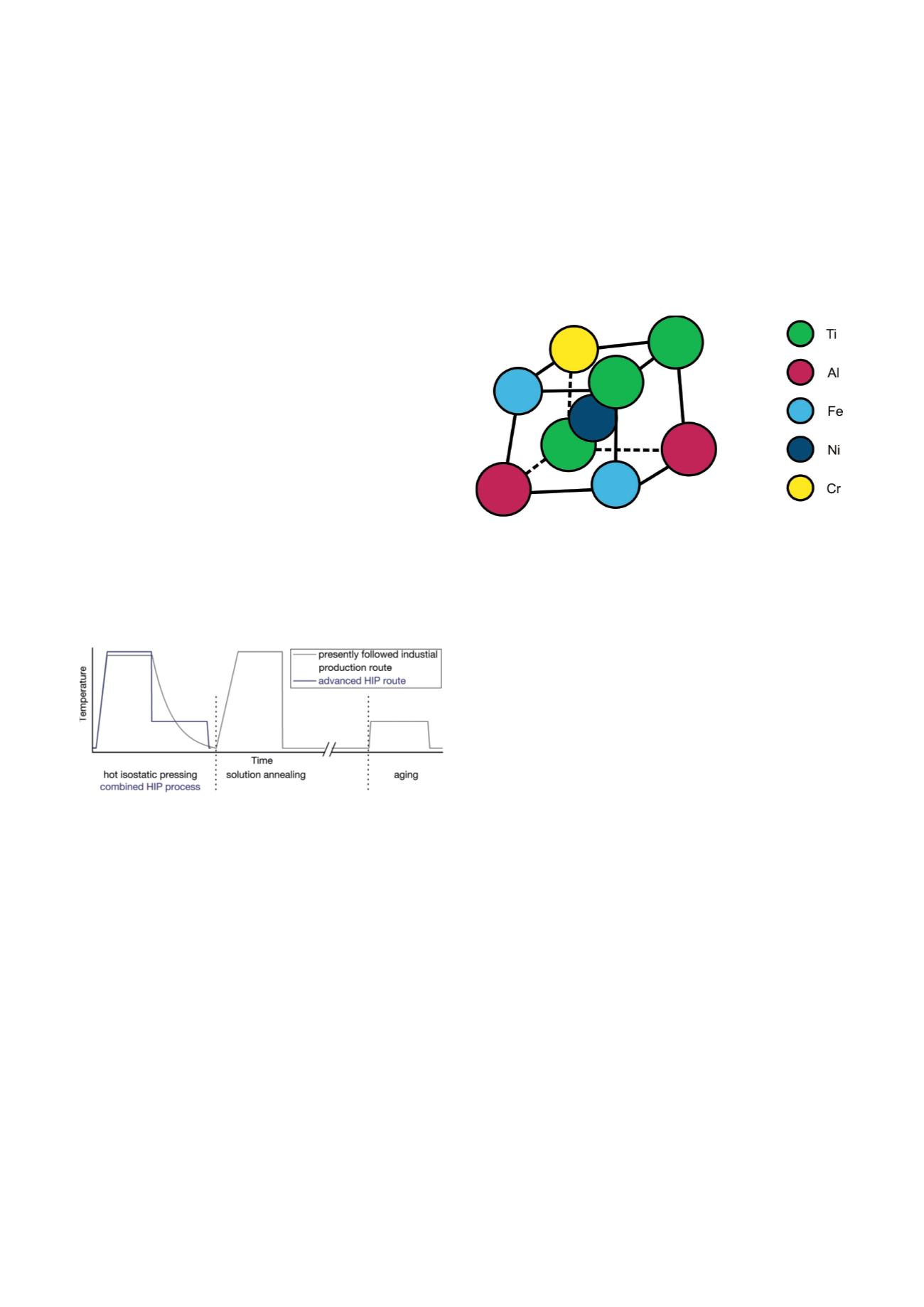

Temperature time profile for the presently followed industrial production

route and the combined hot isostatic pressing process developed at WKM.

(Source: WKM)

an oversaturated condition with magnesium and silicon

atoms dissolved in the aluminum matrix. During aging at

elevated temperatures precipitates are formed that lead to

a significant increase in strength. Due to the very limited

capability to perform rapid temperature changes, standard

hot isostatic presses can hardly be used for a combined

process consisting of densification, homogenization and

aging. With an advanced HIP technology made accessible

to WKM in a joint research project, it became possible

to achieve significantly higher quenching rates in the HIP

process. Mechanical properties characterization at WKM

served to ensure that quenching rates are high enough to

achieve an oversaturated solid solution, which then allows

aging to be performed directly after hot isostatic pressing.

This opens up the possibility to shorten the time at room

temperature between solution annealing and aging.

Thereby, the overall process time can be reduced further

and the material’s strength can be increased within this

fully integrated process.

Partner

■■

Magnus Ahlfors, M.Sc.; Quintus Technologies AB,

Quintusvägen 2, 72166 Västerås, Sweden