226

Thermodynamics

Technology-driven thermo-fluid dynamics research

n

Our research guideline is the proposition that scientific research in an engineering school should

be focused on problems with high technological relevance. A key to realizing our mission is the

close cooperation with industry in general and in particular with partners who – developing their

top-class global products at the leading edge of technology – have encountered barriers that might

be overcome by fundamental research.

Our partner industries are optimizing their technologies

towards a lower carbon footprint, integration with renew

able power sources and environmental compatibility. Their

research needs are reflected in our three research clusters:

The increase of fuel efficiency and operational flexibility

of gas turbines and large reciprocating engines at low

pollutant emissions requires fundamental research on

pollutant formation and emission, reliability, combustion

instabilities and multi-phase phenomena. Safety issues

in nuclear power plants and in the process industries are

addressed by our work on detonation and on two phase

flows. Finally, further research is devoted to the grand

challenge of providing clean water for the world.

The appreciation of our technologically oriented research

approach in the technical community is reflected by two

ASME Gas Turbine Awards for the best publication of the

year on gas turbines and numerous best paper awards

that our research group has received during the past two

decades from several organizations.

Combustion Emissions and Reliability

1. Boundary Layer Flashback in Premixed Combustion

of Highly Reactive Fuels

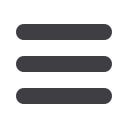

Furthermore, it was shown that the existence of average

boundary layer separation is not a distinct criterion for the

occurrence of confined boundary layer flashback. Instead,

flashback is triggered if local flow separation zones at the

flame bulges are large enough to locally promote flame

propagation.

2. Operational Flexibility of Gas Turbine Power Plants

Motivation and Objectives

To balance the increasing share of volatile power from

renewable power sources, highly flexible conventional

power plants are needed. Gas turbine power plants

have the potential to quickly adjust to changing power

demand but their operating range is limited by emission

Confined flame front at flashback (red) with local flow separation zones (blue)

Motivation and Objectives

If modern gas turbines are operated on highly reactive

fuels such as hydrogen, flame flashback inside the

burner’s wall boundary layer is a major issue which limits

stable and safe operation. A detailed understanding of the

underlying physical mechanism as well as tools to predict

the flashback limits are of great interest in the design of

gas turbine burners.

Approach to Solution

Boundary layer flashback is numerically investigated with

large eddy simulations. Combustion is modeled with finite

rate chemistry including detailed diffusion modelling.

This improves the insight into the mechanisms leading to

flashback.

Key Results

The numerical model can reproduce the boundary layer

flashback limits of flames confined in a duct. All relevant

physical effects are thus accounted for by the chosen

modelling approach.

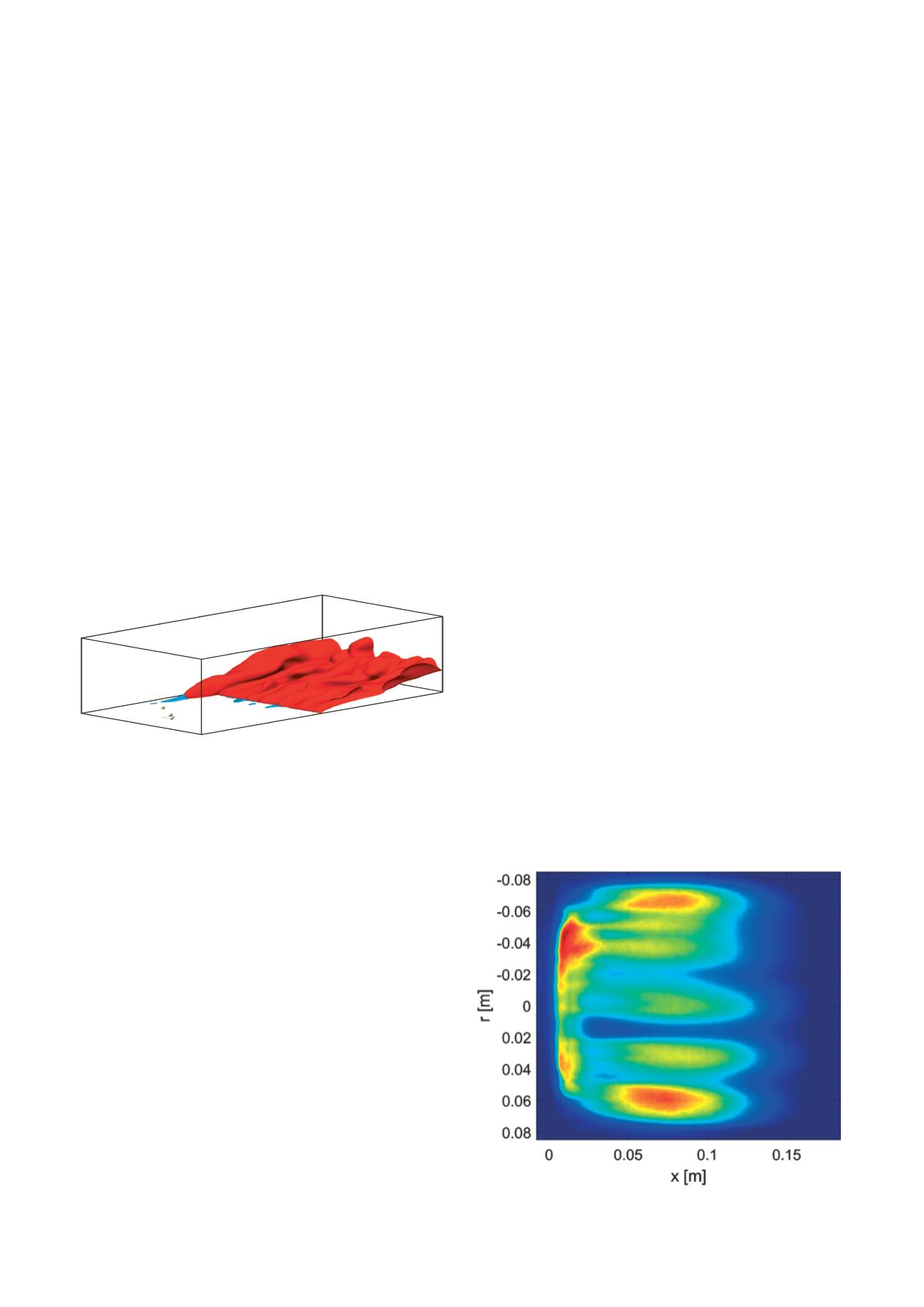

OH*-chemiliminescence of the swirl stabilized jet burner with syngas injection